Drive-train assembling and testing

- Post by: jjust

- 30. November 2020

- Comments off

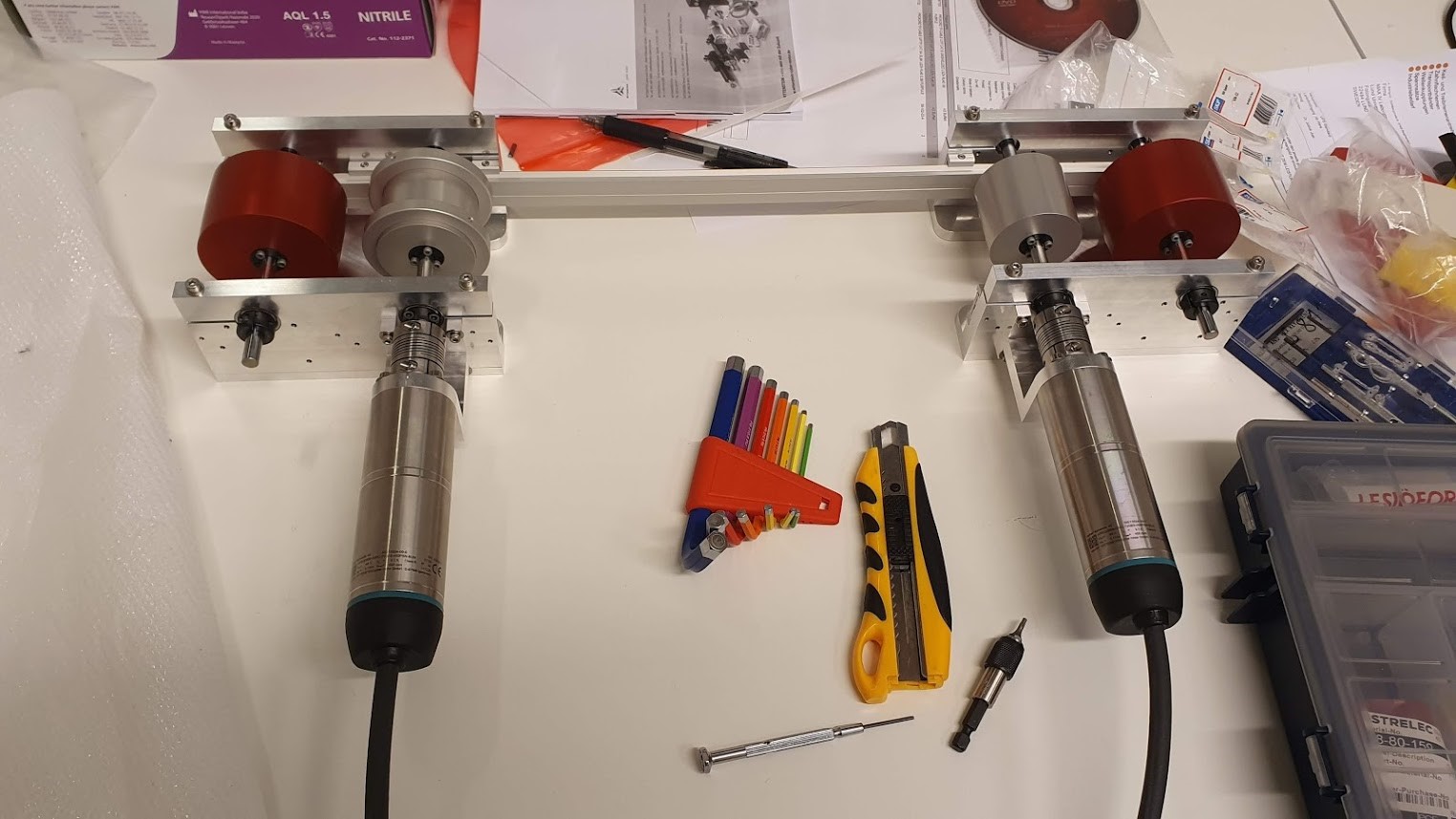

In this phase of the project, the main components of the drive-train (motors, active and passive rolls, frame, bearings and shafts) have been produced and delivered to MAX IV laboratory. Now it’s time to assemble and test everything.

The drive-train of the slot-die coater device will have the task of motion and control of the flexible substrate: this includes controlling the coating velocity and regulating the web tension, both crucial aspects in order to obtain a precise and homogeneous ink deposition and coating process.

The motion control task is assigned to 2 servo motors with proper gears that can regulate both the coating speed and web tensioning.

The four rolls (2 active and 2 passive) are placed in a co-planar axis geometry and with a “live-shaft” configuration.

The two passive rolls (red ones) are shaped with a particular geometry that ensures the flattening and self-centering of the substrate.