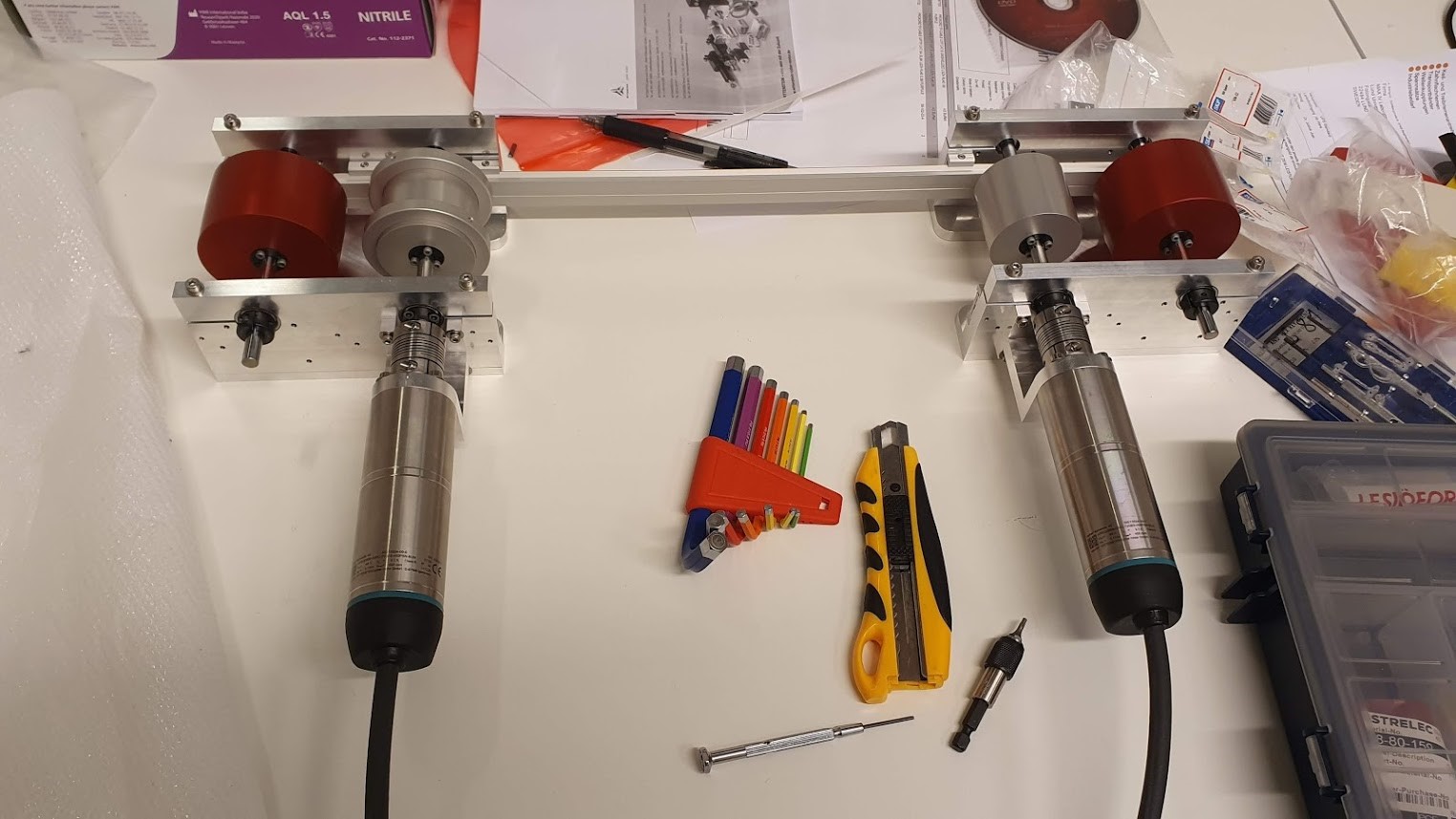

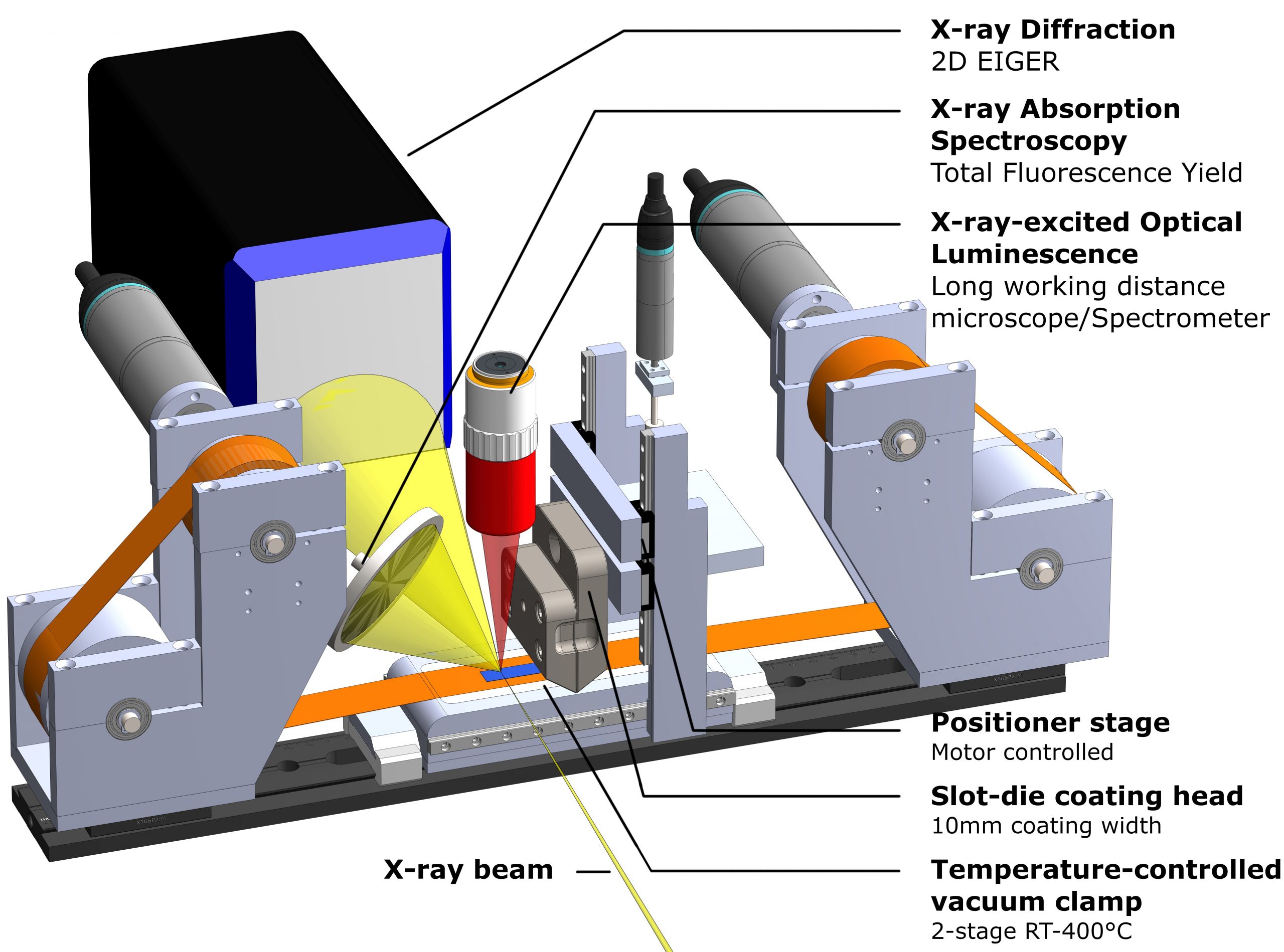

We performed first in-situ coating experiments where we were able to follow the formation of metal-halide perovskites in-situ by means of combined multimodal XAS, XRD, UV-vis and photoluminescence spectroscopy. The newly developed in-situ coating setup was recently integrated into the Balder beamline at MAX IV and can perform coating, gas quenching and annealing experiment in an inert gas environment.…

Updates

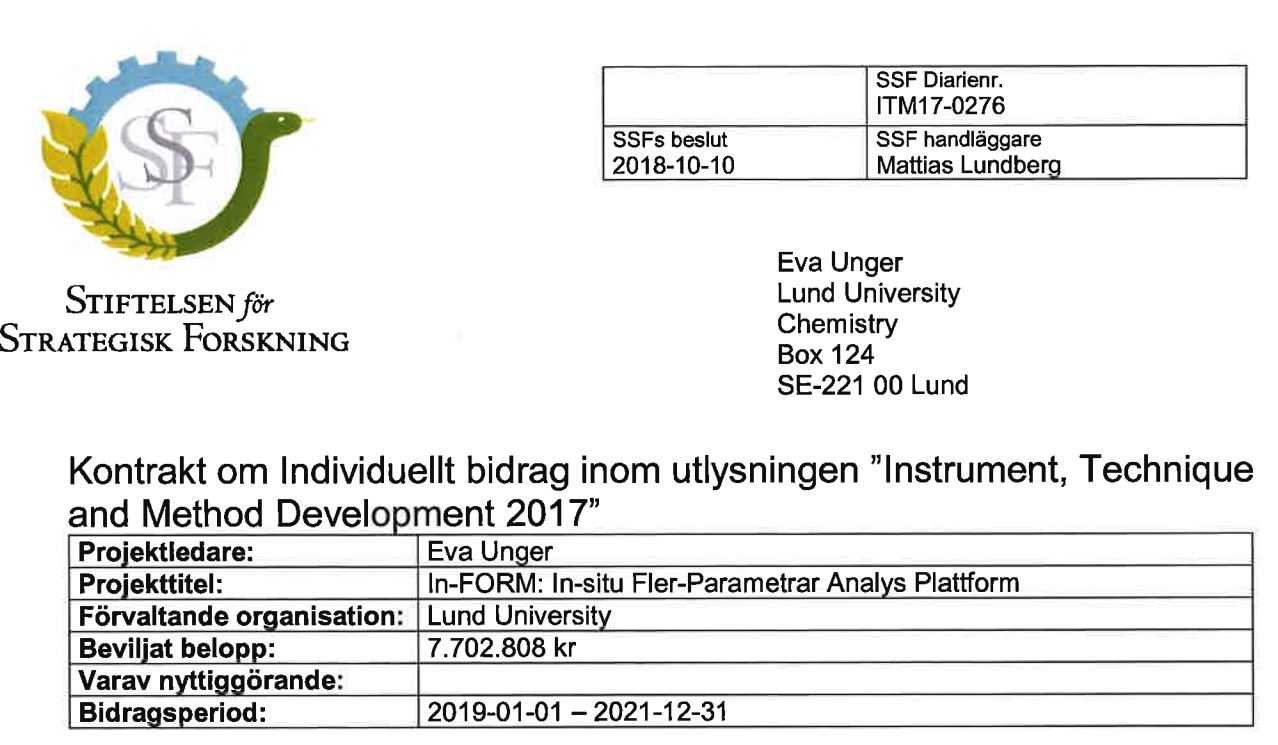

First sucessful multimodal in-situ experiments with the newly developed in-FORM coating device

- 30. November 2021

- Comments off