First conceptual design of the in-FORM coating system is ready

- Post by: jjust

- 10. May 2020

- Comments off

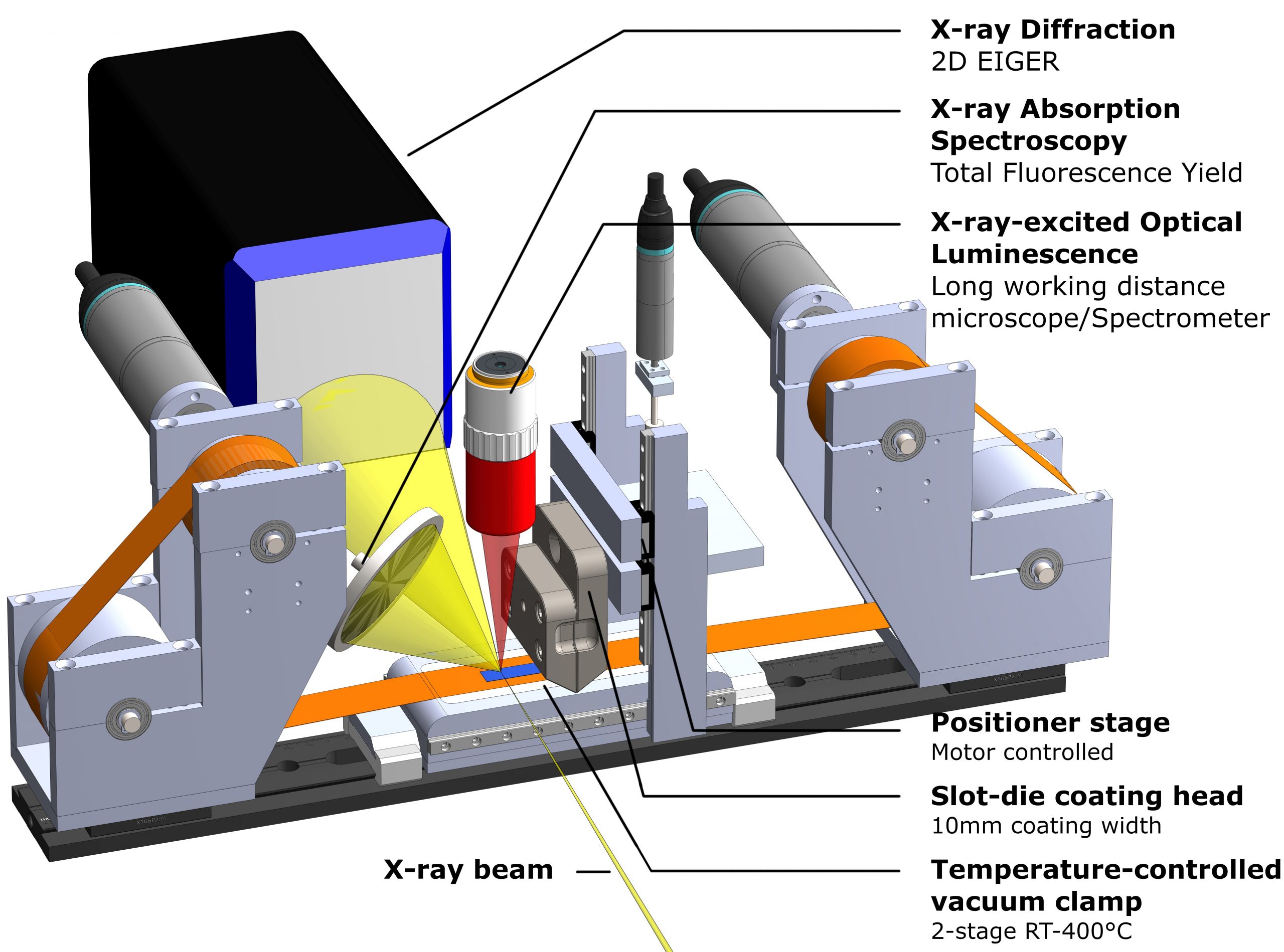

The first conceptual design of the in-FORM slot-die coating platform and possible disposition of scientific instrumentation is ready!

This design will be now presented and discussed with the project team and with community stakeholders, such as FOM Technologies (Company, commercially developing and producing lab based slot-die coating system), Ångström Advanced Battery Centre, Uppsala university (SDC for battery electrode materials), Hybrid Materials Formation and Scaling Group, HZB (SDC for hybrid perovskite photovoltaics). After this discussion phase the finalized design will be converted into technical drawings and the production of the components can begin.

This is an extremely small-footprint coating device, designed from scratch to fit the limited spaces available at the Balder beamline’s experimental hutch. In this configuration the device is about 50x15x20 cm; It will be enclosed in a sealed environment which will assure inert atmosphere (to process O2 and H2O sensitive materials).

The coating device is based on a roll-to-roll configuration. This configuration allows for a wide range of flexible substrates (polymer or metal foils of various thicknesses) and also to small rigid substrates (e.g. glass). Furthermore the rolled substrate guarantees on average 40 meters of coatable material, which means that the device is able to continuously coat ink for more than one hour (with a coating speed of 1cm/s) without the need of substrate substitution or manual intervention of the operator on the device. This is key to obtain highly reproducible experiments with high throughput in terms of scientific data sampling and automation. Another key feature of this design is its modularity. In fact, the device is designed to be adaptable and re-configurable into different geometries in order to be better adapted to different scientific environments and to be able to accept the addition of new modules, such as new detectors (temperature probes, optical microscopes, X-ray detectors) or treatment devices such as hot zones or air-blades.